Driving Green Mobility

A UAE startup takes a creative approach to the petrol-to-electric transition.

By Ben East

PHOTOGRAPHS BY SIDDHARTH SIVA

As dignitaries, politicians and innovators gathered in the UAE late last year for COP28, Dubai’s 11,000 taxis ferried them across the city, to conferences, workshops and talks. But one taxi at Expo City Dubai generated more interest than most.

It looked like a Toyota Camry, but there was no Toyota logo on the bonnet. The front grille had been replaced by a sleek, wraparound bumper. And, tellingly, it barely made a sound. This was Peec Mobility’s ReCar—an ambitious project by Sharjah entrepreneur Zach Faizal to create electric vehicles by repurposing petrol-powered ones.

“There are fleets of taxis, buses and trucks in every major city; public transport is the heart and soul of the mobility sector,” Faizal says from Peec’s base in Dubai, close to Expo City. “But every couple of years they have to be replaced or scrapped. Fine, you might replace them with new electric vehicles to meet climate goals. But there’s a huge cost to that—not just financial, but also to the environment in terms of manufacturing.”

A white paper commissioned by Peec Mobility found that while transportation is the fourth biggest source of global emissions, manufacturing is second. Scrapping old petrol cars for new EVs makes manufacturing, and its emissions, increase. “I thought, why not take these existing assets, repurpose them with an electric motor, and give them an additional life?” Faizal says. “It made perfect sense for me—and for every government’s climate goals—to do something about the 1.6 billion petrol vehicles already on the roads, which will end up being scrapped.”

Peec’s process is more complex than removing an internal combustion engine and replacing it with a series of batteries. The vehicles carry a purpose-built device that cools the batteries to withstand the heat of the Gulf. By targeting large, urban fleets, Peec aims to drive change for as many citizens as possible.

Peec’s process is more complex than ripping out a vehicle’s internal combustion engine and replacing it with a series of batteries. Not least because it wouldn’t work; the weight of the batteries changes the physics of the vehicle. Peec’s approach is less retrofitting, more recycling.

“We like to call it repurposing,” Faizal says. “Say you had a fleet of 5,000 petrol Toyota Camrys you wanted to make electric. We remove everything from the vehicle, 3D-scan the chassis, study the weight distribution, design the electric powertrain components, do some dynamic analysis and testing, and then put the car back together with new suspension, engine bay, cabling and interiors. It’s not a conversion as much as a complete re-engineering of the chassis to produce an electric vehicle.

“The only difference between what we do and a regular car manufacturer is that we don’t have the complexity, costs—and emissions—of building that chassis in the first place.” The process, he says, is 30% cheaper than any new manufactured EV on the market and a vehicle can be repurposed in 80% less time than it takes to manufacture one.

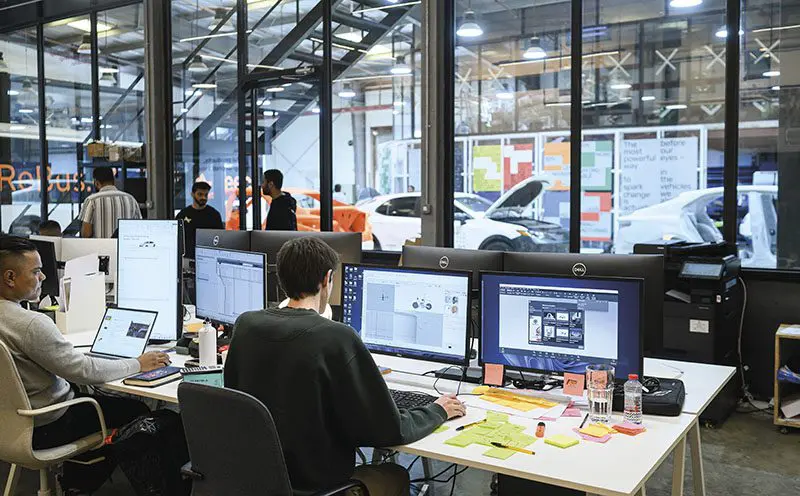

Faizal hatched the idea while studying automotive engineering at the University of Surrey in the UK, and in four years expanded it to a company of 55 people, striking deals with some of the region’s major transport entities.

As COP28 drew to a close, Peec announced its first public-private partnership, with BEEAH Group and the Sharjah Research, Technology and Innovation Park. In the pilot project, due this year, which has additional support from the Sharjah Roads & Transport Authority, the University of Sharjah, and the American University of Sharjah, a BEEAH waste-collection truck will go through Peec’s customised engineering process, called ReMethod, transforming an end-of-life petrol vehicle into an EV.

Peec Mobility’s ReCar—an ambitious project by Zach Faizal to create electric vehicles by repurposing petrol-powered ones.

Repurposing end-of-life vehicles is not about retrofitting, it’s about re-engineering. Repurposing retired vehicles is quicker and better for the environment.

With the successful deployment of the repurposed truck, they will explore the electrification of BEEAH’s full fleet of waste-collection vehicles. The third and final stage—ReSharjah—aims to repurpose vehicles from fleets across the emirate (it will include an R&D component looking at autonomous vehicles, too). As part of ReSharjah, a dedicated facility will be set up in BEEAH’s waste-management complex, powered by renewable energy, that will repurpose large volumes of vehicles.

Faizal welcomes the “momentous partnership” and the shared commitment to sustainable mobility in Sharjah. It will, he says, not only mitigate environmental impact, but will stimulate R&D and—given the academic partners—drive skill development for a greener future.

“I’m proud to be born and raised in Sharjah, this emirate has substance in whatever it tries to do,” Faizal says. “They are serious about the electrification of mobility and reducing emissions, and the UAE can be a model to showcase that. It’s not just about buying a few electric buses after COP.”

Meanwhile, Peec’s pilot schemes with other bus and taxi fleets in the UAE continue. Faizal is driven by the scale of what can be achieved with Peec. “I’m a numbers person, so I needed this to be financially viable,” he says. “While we’re not large-scale production yet—we probably have 100 taxis, 10 buses and five trucks to deliver in 2024—in 2025 it’ll really start ramping up. Then we can start scaling to the world.